Any order placed without an associated computer, will be cancelled.

#Inductive automation ignition upgrade software#

Special bundle pricing: This software must be purchased with an approved Moxa UC-8200, UC-8100A-ME-T or UC-3100 series computer.

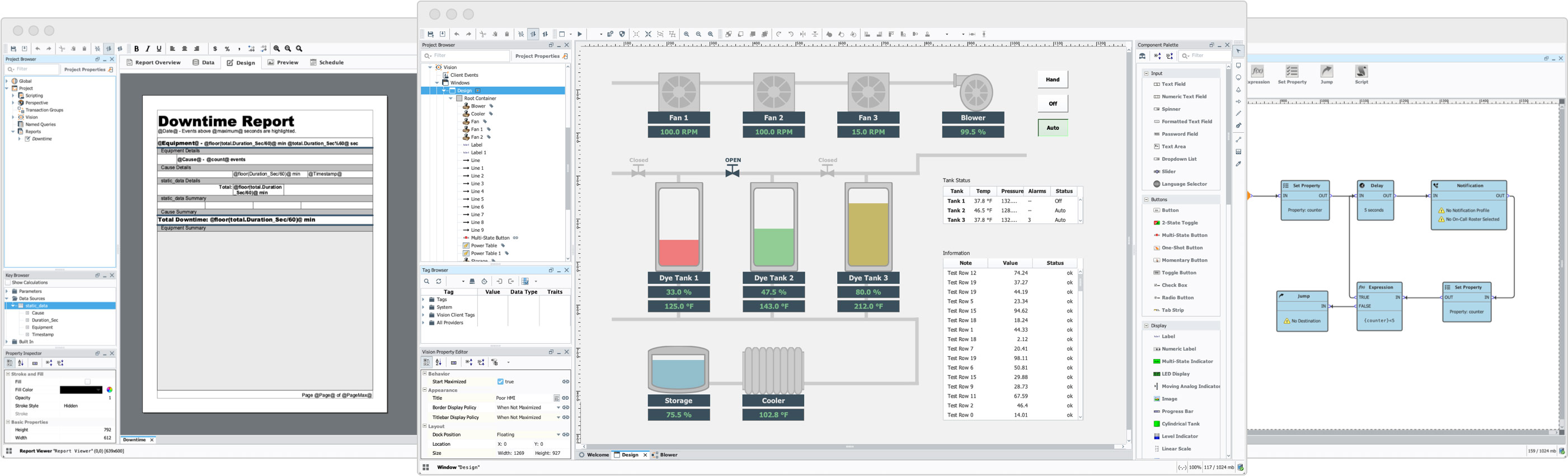

Using Ignition to handle Smithfield’s materials receiving operations, recipes, inventory tracking, product loadouts, historian data analysis, notifications, and visualization, Cox said Smithfield operators now “have the capability to focus on ingredient and product accuracy and production times for the best results.Inductive Automation Ignition Edge software designed specifically for devices used in the field and OEM devices at the network edge.

Smithfield needed to completely automate its hog feed production plant, as the feed mill was working entirely with push button control systems, relay circuit boards, and physical labor.

Travis Cox, co-director of sales engineering at Inductive Automation.As for the data access trend Cox noted, he said industry’s increasing interest in leveraging edge computing and MQTT communications is targeted at bringing data into a modern infrastructure and the cloud for additional applications, such as analytics and machine learning. Inductive Automation’s Ignition Perspective module allows users to build industrial applications to monitor and control production processes from a mobile device, desktop, or touch panel. With a greater focus on mobility, developers are extending automation systems to smartphones and tablets to take advantage of mobile device capabilities such as GPS, the built-in camera, NFC (near-field communication) and Bluetooth, and “leverage those features to build the bigger solution,” he said. Two industrial automation technology trends having a big impact on Ignition are mobility and data access, said Travis Cox, co-director of sales engineering at Inductive Automation.

#Inductive automation ignition upgrade free#

We're also building up our QA (quality assurance) infrastructure with automated test infrastructure and automated benchmarking so that every release we put out has undergone a rigorous set of testing to ensure that Ignition can be as stable and defect free as possible.” At its 2021 virtual Ignition Community Conference, Inductive Automation highlighted the steps it has been taking over the past year to position the Ignition industrial automation software platform for its next steps, indicating that several new updates will be forthcoming in the next few months.Ĭarl Gould, director of software engineering at Inductive Automation.Carl Gould, director of software engineering at Inductive Automation, said, “Our primary area of focus for the software development team is on quality and process improvements.” He said the company has been staffing up the quality team to achieve a “nearly one-to-one staffing ratio of software engineers to test engineers.

0 kommentar(er)

0 kommentar(er)